Inspection Types

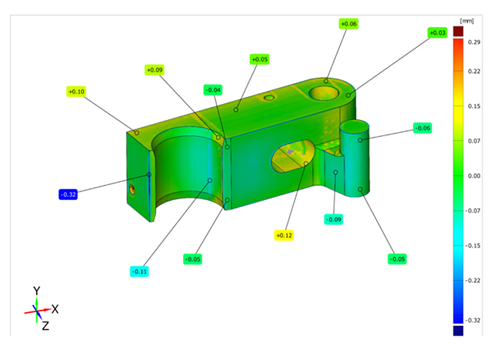

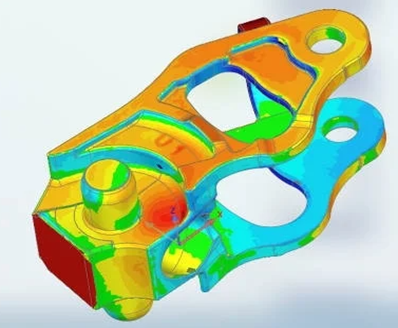

Complex 2D & 3D Measurement

When dimensional measurement matters, trust MQC’s diverse engineering and metrology expertise to deliver the results. All measurements are IAW AC1730 NADCAP M&I criteria. And our systems are certified to their unique industry specifications.

With automated solutions from CMM’s, portable measurement systems and non-contact inspection with a laser scanner or video measuring system, to hand tools, MQC can improve quality assurance or increase inspection capacity. Whether you are facing time constraints or budget constraints, we have the capabilities and expertise you require.

Does your organization need to capture real world quality data for measurement positioning and inspection? MQC’s approach will provide you with actionable information that you can use to improve the manufacturing process.

High Accuracy Bridge CMM

Does your industry require high accuracy and repeatability? Our Bridge Coordinate measuring system can keep pace with the production and quality standards required.

Fully automate the inspection process and know that you have built in quality. Whether you have legacy programs with 2D engineering or MBD/DPD we have the tools and process that meet or exceed your requirements.

Portable Measuring Systems

Portable measuring arms allow you to take measurements directly in the manufacturing environment, where process improvements are the most beneficial and real time.

Our Portable measurement system is the Absolute 7-axis Romer arm with the RS6 structured light scanner. This is the flagship system for Hexagon metrology and a key resource at your disposal. MQC has the technical resources to provide inspection on or off site. Our goal is to simplify the process for our customers. If you need a quick turnaround or data from the manufacturing environment count on us to deliver results.

Ideal for small and medium sized components but with the availability of extended-volume measurement options (i.e. up to 5-10 times the system’s standard volumetric range)

Probing accuracy certified to ISO 10360-12, Scanning accuracy certified to ISO 10360-8 Annex D, the Absolute Arm with the RS6 laser Scanner is truly State of The Art portable measuring equipment.

MQC is proud to not only be a user of this equipment but a distributer of all Hexagon Manufacturing Intelligence Products.

Weldments and Assemblies

The number one challenge with all weldments is warpage. Heat introduced in the welding process causes parts to warp and shrink. MQC has years of experience in collecting data and providing best fit layout dimensions to ensure your welded assemblies make it to the finish line.

Our measuring systems allow for complex measurements that will examine the effects of welding. This of course will give you the trusted information that you need to be proactive with your welding process and tooling.

Let our experienced staff partner with your organization in establishing these critical processes using a data driven approach.

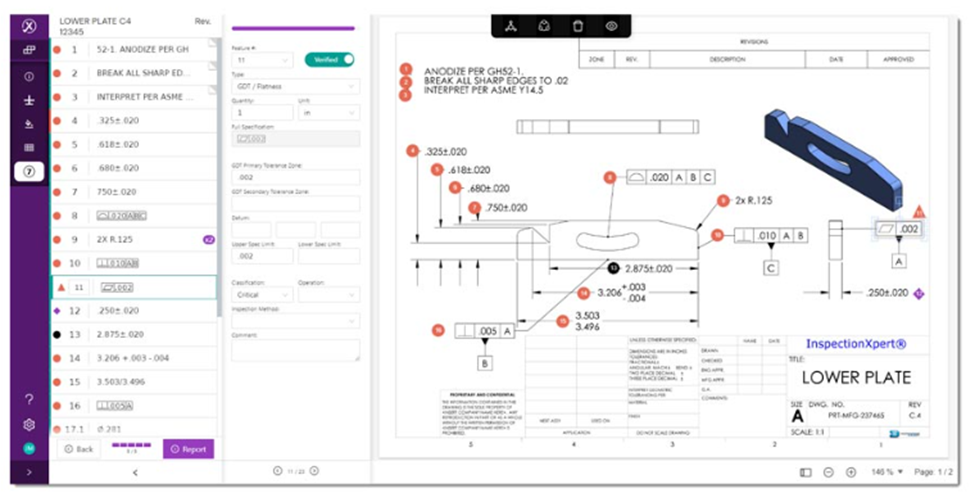

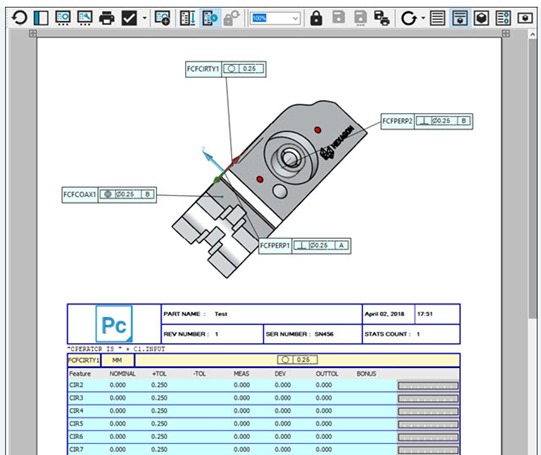

Measurement Software

PC-DMIS is probably the most widely adopted measurement software in the world. We have been using PCDMIS for over 20 years as a measurement software of choice. Utilize our experience with this tool. We can provide training to your staff, create DCC programs, establish inspection plans for your portable device, or inspect your products for you.

MQC also supports Starrett XYZ, Polyworks and Verisurf.

(Statistical Process Control) We recognize the roadblocks in the manufacturing environment to implement statistical process control. MQC has a complete toolset to offer your organization the ability to manage inspection data. If you need statistical evaluation (provided with automation) that suits your business size and needs, we have the solution. With a proven track record and a highly trained staff of inspectors and engineers we can take your SPC program to the next level.

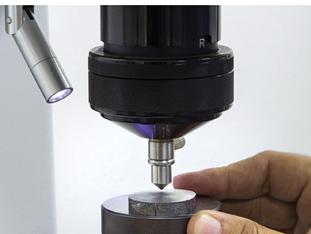

Surface Analysis

Discussions on the quality of surface finish normally evolve around the measure of roughness. The most common measure of surface finish, and parameters such as average roughness (Ra) and mean roughness depth (Rz) are the most required. But the ways to measure a surface and the reasons for doing so go far beyond roughness.

MQC has many years of experience in providing our customer the analysis they need. If it is a common or complex measurement we have the capability to ensure your requirements are satisfied

Currently there are more than 100 recognized surface finish parameters. Most were developed to analyze and provide solutions for specific manufacturing problems or to assess the capability of a surface to perform a desired function. Some have extremely limited application, others have become obsolete and, as manufacturing processes evolve, still others are being developed. Some of the most sophisticated of these, which are providing critical control data at major manufacturing facilities today, have yet to even find their place among defined standards.

These surface finish parameters can be measured and analyzed using State-of the Art Ziess surface analyzer.

Hardness, Material & Conductivity Testing

Rockwell Hardness testing is a very practical method that can give you fast results when attempting to certify material hardness. MQC is equipped with what is needed for a smooth flow of production. All Equipment and standards are certified to NIST and inspections are performed IAW Nadcap measurement and inspection criteria.

- HRC testing A Scale

- HRC testing B Scale

- HRC testing C Scale

- Brinell

- Vickers

- Micro Hardness

- And more…

We offer conductivity measurement using the latest measurement equipment, we can comply to any industry specification.

MQC can also advise on the hardness & conductivity measurement solution for your organization. With knowledge of many different pieces of equipment and price points, let us assist in finding the right hardness tester for your operation.

Quality Engineering

What is a Quality Engineer and what do they do? They engineer quality into business processes. Quality Engineering will also check to ensure processes stay compliant. MQC has the engineering staff that can assist your organization to build quality into your process and verify its compliance.

Often, Quality Resources are consumed with the day to day activities or busy putting out the most recent fire. All the while your core processes suffer. How will this be corrected without adding resources? Before you add to your team consider partnering with MQC to determine your course of action for the upmost success.

Quality can help build and facilitate:

- Organizational Management & Planning

- Risk & Opportunities

- Strategic Direction

- Employee Development

- Contract Review

- PPAP & APQP

- Calibration systems

- Document Control

- First Article/ AS9102

- Receiving Inspection

- Automated and Mechanical Inspection

- In-Process Inspection Planning

- Sample Inspection Planning

- Certified Operator Program

- In Machine Measurement systems

- Non-Conformance Handling & Returns

- Root Cause Correction

- Continuous Improvement

- Data Analysis & Evaluation

- Audit Planning & execution

- Management Review

Take your current systems and develop them into robust viable operations. Use data to make decisions. Be proactive in addressing the risks and opportunities that face your business and implement solutions that have the long term in mind.

Supply Chain Services

What is the engine that drives your continued business improvement? Let MQC partner with you in strengthening your supplier network. We can assist in integrating a data driven approach to provide immediate identification of abnormalities and trends within your supply chain. Whether it is Sources Inspection, FAIR Management, Supplier Corrective Action, Risk Assessment, or Supply Chain Auditing, supplier performance and the building of a strong network is essential to any business. Unfortunately, there are variables that prevent business from extraordinary supplier performance. The lack of resources amidst the daily grind or the effectivity of overburdened departments cause companies to operate outside of their own planned arrangements, leaving management without accurate data and tools to improve.

Let MQC assist in achieving your Strategic Supply Chain Objectives

- Improve customer satisfaction

- Improve On-Time-Delivery

- Improve Product Quality issues

- Accurately track supplier CoPQ

- Strengthen Relationships with suppliers

- Manage Supplier data with built in escalation

- Proactive measures

Our team of Certified Quality Engineers have extensive training and experience in process integration to meet the specific business needs that you have. Strategic Planning for any business needs a structured process approach. If the decision-making process in your business is not based on real time data, then contact us to assess your situation and tailor a plan for your future success.

MQC Calibration Serving Clients Nationwide

Inspection non-contact capabilities include:

Laser scanner 0 to 8 foot ±5 ppm

Optical CMM ±50 ppm

Let MQC partner with your organization to handle all your Quality Assurance needs